Fertigation

The technique

In the broadest sense, fertigation is a technique where various substances are mixed in with irrigation water and then distributed to crop growing areas through the reticulation system. It’s easier to implement where all additives can be dissolved, but slurries are also used, eg in organic horticulture, provided particulate size is limited and emission jets are of sufficient diameter. However, such applications require constant agitation to avoid unequal delivery or formation of sediments that could block the irrigation lines. The present discussion will focus solely on use with soluble chemical fertilizers. Fertigation is mainly used in high value crops such as fruit and vegetables where the costs of installation, use and maintenance make economic sense.

It has several advantages over the more conventional approaches of periodic granular or liquid application of chemical fertilizers, or reliance on organic matter to supply nutrients. These include:

- Labour and time saving – all the distribution is done by an installed reticulation system, rather than having to go round the whole area spreading agents each time.

- Even distribution – with good sprinkler or dripper design that ensures all areas are covered when watering, the contained fertilizer is similarly evenly delivered. This compares with, say, hand application of granules where there may be concentrated spots and others that contain very little. Hot and cold spots are further likely with solid applications when these dissolve with watering, such that soil regions close to the granules may have very high and damaging levels. For example, boron is one micro-nutrient where the window between deficiency and toxicity is quite narrow. Plus this problem of hot spots can be repeated at lower soil depths with wet dry cycling, when dissolved fertilizer may crystallize or precipitate back out of solution before being dissolved again in the next wet cycle.

- Minimise fertilizer requirements in that delivered amounts are closer to what plants can take up. This can often be less than one half of conventional means. Because of the more regular and even applications of lower concentrations, root growth and spread can be more profound, leading also to water savings. Both of these factors lead to decreased costs.

- Faster action as nutrients can only be taken up by plants when in solution

- The lower concentrations cause less damage to delicate young plant feeder roots, and also soil microbiota. High viable levels of the latter are essential to maintain soil health, productivity and resistance to pathogens. Areas that have relied exclusively on chemical fertilizers have ever-decreasing microbiota populations over time.

- Reduces leaching of excess nutrient through to the water table with resultant pollution of aquifers, lakes and rivers.

- High local dissolved concentrations when fertilizers are applied as solids can more strongly drive complexation and precipitation reactions which result in nutrients being present in the soil but essentially unavailable. Lower concentrations from fertigation minimise this problem, allowing more uptake from solution by plant roots and microbes, and later supplementation by the organic and clay matter CEC reversible adsorption systems which act as sinks or buffers.

- Unless coastal sands have been improved by adding clay and organic matter, they have very low nutrient retention and so require frequent administration for plant supply. Soils with naturally high CEC can get by with infrequent administration, sometimes only once or twice a year as their high retention allows these nutrients to be subsequently released for plant uptake for a considerable time afterwards. The ‘more frequent, lower application rate’ strategy is ideally met with fertigation.

- If low pressure sprinklers are used that also moisten crop foliage, low fertigation concentrations will not cause leaf burn and have the additional benefit of rapid effects through foliar absorption.

- Nutrient supply can be precisely matched to plant needs in different seasons.

Disadvantages are:

- The additional cost of installing and maintaining a system that delivers fertilizer into the irrigation line – assuming a reticulation system has already been installed because of general watering needs. In commercial orchards where costs of labour, machines, fuel etc have to be accounted for, fertigation often becomes very much the cheaper of the two. In the hobbyist/backyard situation where costs are not directly counted, this issue becomes less critical.

- In adding chemicals to the irrigation water, there is the risk of crystallization and/or precipitation in the lines causing blockages. As with ordinary reticulation systems, delivery points have to be checked periodically to ensure patency. Depending on solutions used and the scale of operations, some users routinely flush out the system after every application, but if fertilizer concentrations are kept low and low pressure sprinklers with large jets are used this problem is vanishingly small.

- As described below under Solutions, most systems require concentrated solutions such that after dilution in the main lines sufficient fertilizer is delivered. This requires considerable care as many salts have intrinsically low solubility, and this can be made worse when mixed in with all the other nutrients producing various insoluble complexes.

- It will not generate quick results.

Fertigation is essentially somewhere between the organic and hand/machine spreading of granular chemical fertilizer approaches, and cherry picks some key features of each. With the former there’s little control over timing of soluble nutrient release for uptake by plants at critical growing and fruiting periods throughout the seasons, whereas in fertigation it can be as precise as needed; both these approaches minimise leaching of nutrients below the root zone. The chemical approach gives better control of nutrient uptake than organic but is not as good as fertigation because the dissolution process can complicate uptake. Solid chemical fertilizer application can result in substantial leaching losses and is more harsh on plants and soil, whereas with fertigation this is minimised.

Nutrient delivery

To deliver fertilizer solution into the irrigation lines, a number of approaches have been used.

The simplest system is where irrigation water is pumped from a large tank, eg several kilolitres in a backyard setting. In this case it’s merely a matter of dissolving all the chosen ingredients in a large volume of water, adding to the tank and ensuring adequate mixing before use. The existing pump then distributes all at the scheduled times and the tank is then refilled offline, ready for the next session.

If a large tank is not available or feasible, then a system has to be selected that will deliver fertilizer solutions to the main irrigation line. Because this line operates under pressure from the pump (bore, pond or river water source), an injection system drawing from a nutrient reservoir is needed that can counter or use mainline pressure such that input occurs. A one-way valve should always be installed in the mainline, upstream from the injection system to prevent nutrient backflow when the system is not running as this could result in aquifer contamination.

Conceptually, the simplest approach in this scenario is to have an electric pump which injects given volumes of fertilizer solution from a reservoir into the main line. Preferably the speed of the pump should be adjustable to allow exact control over how much is delivered. Limited control may be possible with a one-speed pump by having a tap in the delivery line, but this will depend on how much back pressure the pump and line can withstand. Alternatively, control can be achieved by adjusting the concentration of fertilizer in the reservoir solution or regulating flow in the mainline with a tap. A one-way valve in the delivery line will prevent any water in the mainline from diluting the reservoir when the injector is not running. Disadvantages are the need for installation by an electrician, the need to ensure mains current in a wet area remains active and effectively insulated, and any pump maintenance or malfunction repair.

Two other common approaches use the flow of water in the mainline to provide the means of injection. With both it is preferable to have a side line loop installed near the bore head or water supply source; fertilizer is then delivered into the system through this sideline. Within this loop, there should be a tap in the mainline and another in the sideline upstream from the injector, so that relative flow between the two parallel lines can be adjusted. This helps control how much fertilizer is injected. A one-way valve should be installed in the side line down-stream from the injector to prevent backflow or recycling of mainline water back towards the injector.

In a venturi system there is a gradually reducing diameter restriction in the side line which generates a relative vacuum that sucks in fertilizer solution from the reservoir. The rate of nutrient solution delivery is controlled by water flow rate and the degree of restriction. The big advantage of this approach is there’s no moving parts, so it’s maintenance-free. The disadvantage is that the restriction causes some loss in line pressure which might mean sprinklers don’t cover their intended area or function properly. However it might be possible to offset this by increasing the number of reticulation stations.

The second approach is to use the flow of water into the sideline to drive an impeller that in turn drives a pump for injection of nutrient solution from the reservoir. The volume of solution delivered depends on the sideline flow rate, which can be adjusted using the mainline and sideline taps. This has advantages of not having to isolate electrical components in the area, and compared to venturi systems the negative effect on mainline pressure is less. Disadvantages are that the pump may require maintenance or replacement if worked too hard by having too high a sideline flow rate, and pump seals may become less effective and require replacement.

Stock solutions and calculations

These have been formulated for an injector system where sufficiently concentrated solutions are required to ensure adequate fertilizer will be delivered after dilution throughout the irrigation system. They’re suitable for the Perth coastal sand plain where bore water and/or soil may be alkaline due to the presence of limestone. Other areas may not have to consider alkalinity. Fertigation solutions should be complete, with all macro-, meso- and micronutrients present. In concentrated solutions, the solubilities of individual ingredients and the formation of various complexes between the different ions may cause precipitation, and preventing this is a considerable challenge. My approach has been to avoid putting them all together with use of three stock solutions that are each rotated, one week at a time. You could avoid the do-it-yourself complications by simply purchasing a complete liquid fertilizer (ie with trace elements) of sufficient strength for fertigation. But you’ll pay heavily for the convenience compared to buying the base ingredients separately in bulk quantities.

The three stock solutions are:

MACRO/MESO – for N, K, Mg and S

MICRO – all trace elements, and

PHOSPHOROUS

The quantities below are to make up 3L of stock for each.

For the MACRO/MESO stock solution, starting ingredients are:

800g KNO3 – 13.5% N, 46.2% K

500g Urea – 46% N

50g (NH4)2SO4 – 21% N, 24% S

300g MgSO4.7H2O – 9.8% Mg, 13.3% S 30ml HNO3 (68%, density 1.4) – 15% N Giving totals of:

N = (800 X13.5%) + (500 X 46%) +(50 X 21%) + (30 X 68% X 1.4 X 15%) = 348g

K = (800 X 46%) = 368g

Mg = (300 X 9.8%) = 29.4g

S = (50 X 24%) + (300 X 13.3%) = 52g

MICRO

(Mirco trace element mix – 1st 4 elements supplied as chelates)

300g containing

Fe – 5%

Mn – 3.5%

Zn – 2.5%

Cu – 1.0%

B – 0.65% as borate = 0.11% as B

Mo – 0.3% as molybdate = 0.18% as Mo

Giving totals of

Fe = 300 X 5% = 15g (5000ppm)

Mn =300 X 3.5% = 10.5g (3500ppm)

Zn = 300 X 2.5% = 7.5g (2500ppm)

Cu = 300 X 1% = 3g (1000ppm)

B = 300 X 0.11% = 0.33g (110ppm)

Mo = 300 X 0.18% = 0.54g (180ppm)

Librel is an alternative mix that could be considered.

PHOSPHOROUS

P = 90ml H3PO4 (85%, density 1.68) 31.6% P

Total P = 90 X 1.68 X 85% X 31.6% = 40g

The MACRO/MESO stock contains the nutrients N, P, K, Mg and S in the approximate ratios of 12:1:12:1:2. It contains both NH4 – N and NO3 – N as most plants prefer a mix of the two rather than one or the other. Demand for K is high in fruit trees, so considerable KNO3 is incorporated, with the added benefit of NO3 – N to complement the supply of NH4+ – N from urea and (NH4)2SO4. Our coastal sands are particularly deficient in Mg so this meso-nutrient has to be specifically addressed. A similar situation exists in the sands of Florida where base fertilizers (those not including trace elements) are specifically formulated with Mg, so mixes will quote ratios of the four elements, eg 15:2:12:1 for NPKMg. The MICRO formulation really requires most salts to be in the form of chelates to avoid precipitation in concentrated stock solutions, and also to avoid precipitation in the soil, particularly if pH is alkaline. Sourcing the chelates individually can be expensive and the prepared mix is a suitable compromise. The problem with pre-made mixes is loss of control of element ratios, but this one is reasonable. The PHOSPHOROUS stock is the easiest way to include P without precipitation from other elements in concentrated solutions, and it contributes slight acidity.

N is lower here than in many commercial soluble fertilizer products (eg Yates’s Thrive) but when distributed through the irrigation it’s delivered more frequently than conventional periodic hand or solution application. The other meso-nutrient Ca doesn’t really have to be provided as it’s everywhere in our coastal sands, to the extent that its alkalizing properties usually need addressing. In addition, dolomite (Mg and Ca) can be sprinkled around once or twice a year when new batches of compost are applied throughout the garden. This also addresses the low Mg levels when compost relies substantially on local grass clippings, but remember that dolomite is alkaline.

The buffer reserve in calcareous alkaline sands that many of us experience near the coast is so large that it’s not possible to permanently reduce pH, short of removing it all and replacing with better loams – an impossibly costly and disruptive exercise. The best we can hope for is more temporary adjustment throughout the growing seasons by adding powdered S which thiobacteria slowly convert into acidic sulphate. Fertigation is not a preferred technique for adjusting soil pH, primarily because of the corrosive nature of acids resulting in more rapid breakdown of pump seals, diaphragms etc. Scheme water in my area has a pH of 7.6, within the range of 7.3-7.8 quoted by the Water Corporation. My bore water at the sprinkler head is in the same range, ie slightly alkaline, so the HNO3 and H3PO4 acids included in the stocks ensure that at least the reticulated water is not more alkaline when delivering all the nutrients. HNO3 is by far the stronger acid of the two, but there’s a limit to how much should sensibly be included. With the present addition the stock pH is 1.7 – as low as I’m prepared to risk it.

Each of the three stocks is used a week at a time, rotating as MICRO, MACRO/MESO, PHOSPHOROUS AND MACRO/MESO – ie a 4-weekly cycle.

How much do these solutions contribute to my yard of approx 500m2 per month? In the hot months of the year, I run my bore delivering 80L/min for 50min sessions, 4 times/wk = 4kL water/session. This is equivalent to roughly 8mm precipitation. In peak summer days, pan evaporation in Perth can be 12mm or more. About 2L of concentrate is used per week, so with my 4-week rotation system this means approx 463g N, 27g P, 489g K and 40g Mg is delivered/mth. When moving out of the maximum growing period into the cooler months, I decrease delivered nutrient amounts by reducing run times, dropping back to 3 sessions/wk and changing the relative water flow through the main- and side-lines. Of course with winter watering restrictions the system is turned off, but for the evergreens from cooler climates that continue to grow slowly and still need some fertilizer, I rely on my heavy composting and retained nutrient build-up.

How do these fertigation rates compare with what has been reported as desirable for fruit tree yield elsewhere?

N is the single most important nutrient variable for yield (provided other nutrients are not limiting). The average N fertilizer rate for most tropical and sub-tropical fruit trees is about 100kg/Ha/year. Some nutrient-hungry crops like passionfruit might need 2-3 times this amount. The above fertigation rate of N when run for 8 months of the year represents about 76kg N/Ha/yr. So although less than the quoted 100kg, good composting can make up much of the difference. Remember also that fertigation will need less fertilizer than that applied in granular form for equivalent fruit yield. If you decide to fertigate, you should go through similar calculations to ensure that what you’re delivering is meaningful, taking account of your soil fertility, delivery system and watering schedules.

Fertigation is a ‘slow and steady’ approach, so if you want results next week you’ll be disappointed. There are many ways you could speed up the action but if taken too far they inevitably have some disadvantages. For example, with tank delivery systems it’s relatively easy to add larger quantities of nutrients without precipitation, given the large water volumes. But if the sprinkler system also wets foliage then the possibility of leaf burn with higher nutrient concentrations needs to be kept in mind. Plus the problem of jet blockages increases as concentrations increase. Precipitation and solubility limits figure more strongly with concentrated nutrient reservoir delivery systems. You could also increase the session run times or their frequency. With the former the possibility of nutrients being delivered below root zones should be recognised, especially with dripper systems and where soil water retention may be low. Increasing frequency has to comply with prevailing government water restrictions. Probably the surest way to speed and enhance growth if desired is to let fertigation carry the base load of fertilizing year round with supplementation by organic matter that has good nutrient retention characteristics, and only then adding granular forms sparingly if you’re sure they’re needed or you’re impatient for results. Fruit trees operate on yearly time scales, not weekly, so what’s best for the long haul is the wiser strategy!

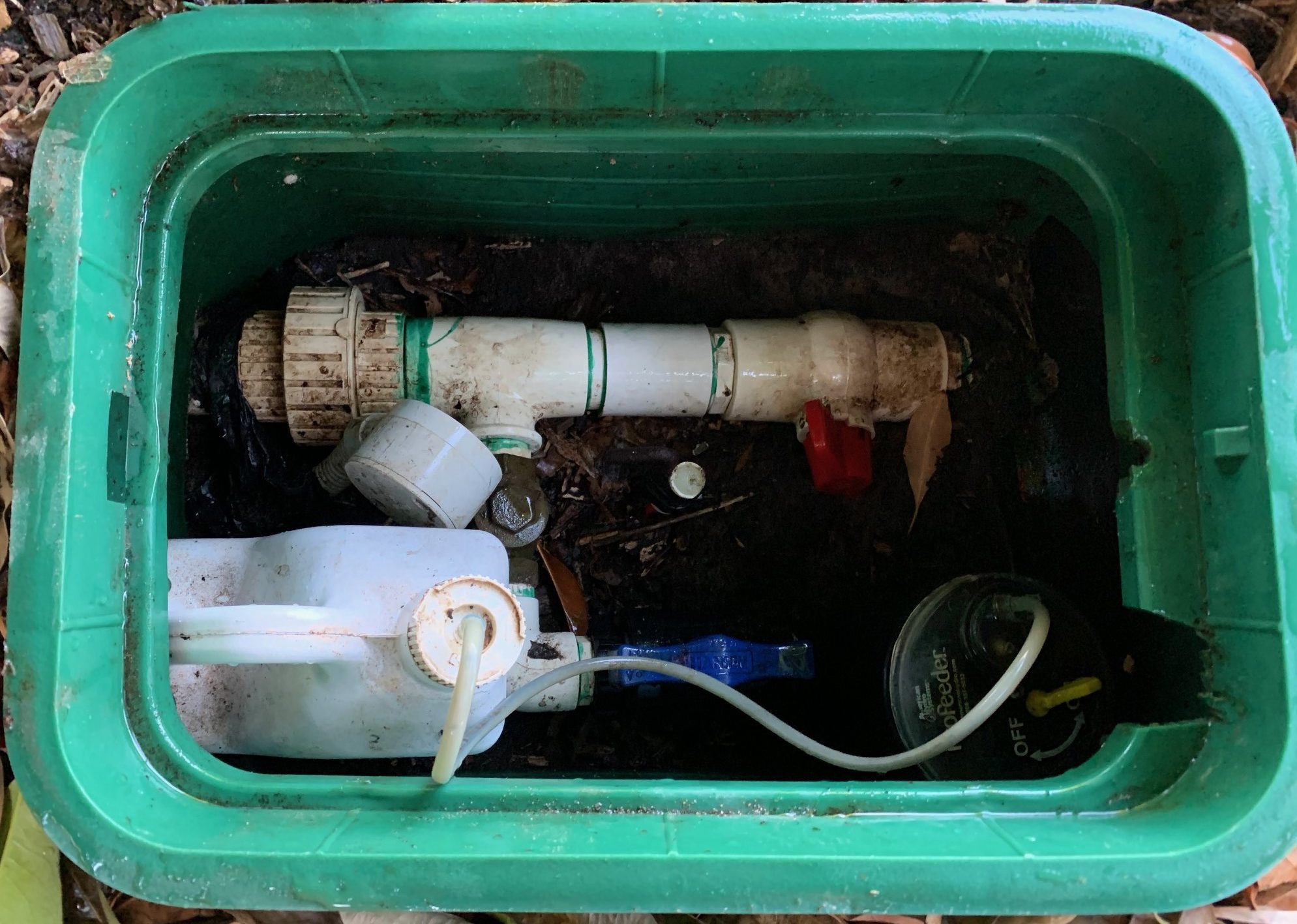

Hydraulic-driven fertigation pump set-up. The nutrient reservoir is on the left with a delivery line to the pump which is in the lower right hand corner. Water from the bore runs horizontally from left to right in the mainline across the top and the smaller sideline looping off it is below. The taps allow control of relative flow between the two lines, and the brass check valve preventing nutrient backflow can be seen upstream from the pump.